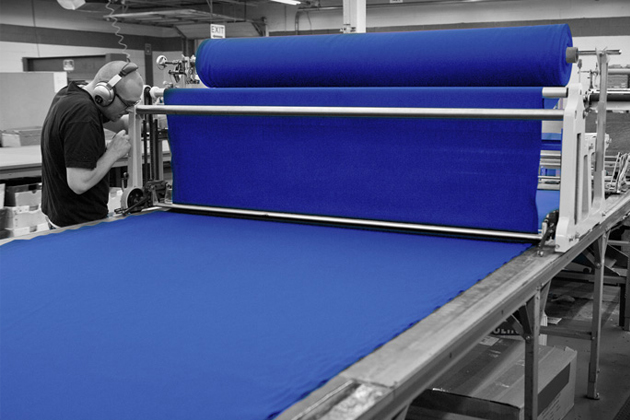

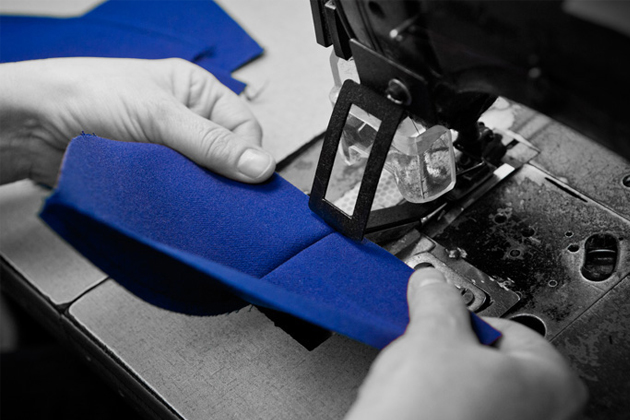

New Era‘s Japan branch recently gave us a look at the 22 steps involved in constructing one of their signature 59FIFTY caps. Throughout the process we see the material slowly take shape until it becomes one of the brand’s fitted caps featuring an embroidered logo and a stitched New Era flag. Branded taping and a moisture-absorbing sweatband line the interior.